Yamaha Motor Company Releases Newsletter Detailing Next Generation Ergonomically Designed Handlebar Switchbox

Yamaha Announces Thrilling New YZF-R7 AND All-New Adventure-Ready WR125R Dual Sport

November 4, 2025

Yamaha WaveRunners Rack Up 25 Podiums at IJSBA World Finals

October 28, 2025

Yamaha Outdoor Access Initiative Celebrates National Public Lands Day by Completing Employee Volunteer Trail Workdays in California and Georgia

October 8, 2025

Yamaha Marine wins innovation award for Helm Master Ex wireless control system

October 7, 2025

Yamaha Unveils 2026 Side-by-Side Vehicles: Proven Off-Road Excellence

September 10, 2025

Yamaha Announces 2026 ATV Lineup

September 10, 2025Intuitive Usability for Lowering Rider Stress and Contributing to Purer Riding Fun

The Human–Machine Interface Group at Yamaha Motor’s Functional Module Development Division conducts ergonomics-based research on the functional components of motorcycles and other products that serve as key points of contact between the user and the machine, like switches, levers, and pedals.

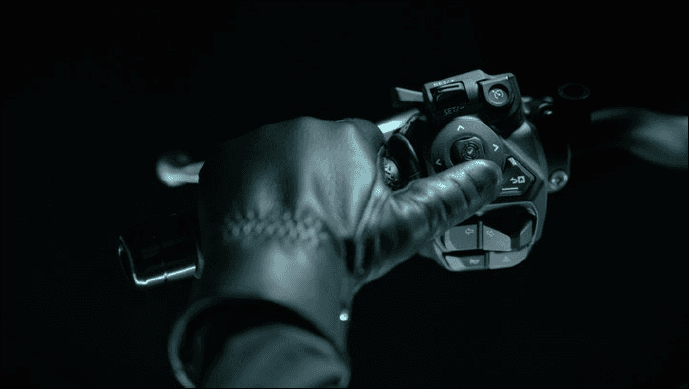

One of the results of their R&D was an all-new next-generation handlebar switchbox, which made its debut on the new MT-09®. The switches were designed to thoroughly reduce stress and unwanted distractions for the rider in their operation and thereby enhance the joy of motorcycling.

Seeking to Create a Next-Generation Switchbox

![]()

“While it’s only tacit knowledge, placing importance on parts of the vehicle that people touch and interact with is deeply rooted in Yamaha Motor’s Monozukuri culture, and I feel it’s also one of the traditional ways we do things here,” says NAGASAKI Yoshitaka.

He is part of the Functional Module Development Division’s Human–Machine Interface Group, which is responsible for ergonomics-based R&D of switches, levers, pedals, and other various functional components that serve as the points of contact between a user and their machine.

When riding a motorcycle, the rider operates various switches and controls while maintaining a firm grip on the handlebars. These range from using the turn signals, lights, or horn to switching between different ride modes, and all of this must be done while properly riding, turning, or braking with good control. To prevent misclicks while creating a layout and switch shapes that are natural, pleasing to the touch, and easy to use, it is essential to first gain a deep understanding of the human body and its senses.

“In the past, we tried using or adapting existing parts to best fit each product,” says Nagasaki. But with the switchbox on new MT-09 and XSR900GP, “we built it from scratch aiming to create a next-generation switch scheme that could possible become the standard in the future.”

“We wanted just using the switches to contribute to a purer riding experience,” explain the team that developed this next-generation switchbox.

Like Nagasaki said, placing importance on parts of the vehicle that people touch and interact with is part of our Monozukuri culture. For example, while Yamaha’s first product—the 1995 YA-1—was modeled after the German DKW RT-1, it was given Yamaha-original designs for

Aiming for Intuitive and Universal Usability

![]()

Designing and engineering switches is a remarkably delicate process. For example, in analyzing how a thumb works to pull a switch, the rider first lightly places their fingertip on the switch to feel it out and confirm placement before then actually starting to pull with the thumb. Additionally, it is also important to design the switch to have the rider’s finger stop said pulling action in a way they find natural. To find the optimal solution, the team built clay models and scraped away at them, the shavings sometimes so thin that they were nearly transparent. This delicate process of exploration was conducted over and over.

A similarly meticulous approach was also taken for adaptability and versatility, with repeated verification tests run on the track to assess a variety of specs and settings accounting for differences in finger lengths, glove thickness and construction, and more. “Slight differences in a switch’s stroke or clicking feel can make just a single push feel nice or unnatural,” explains IKEYA Ryosuke. ”That’s why we brought a number of different switch specs to compare during testing.” His colleague, HORIUCHI Tomotaka, adds: “We put the internals for our switches together using FPCBs that can be twisted so that what we created wouldn’t be compromised by purely mechanical requirements. As a result, we were able to put together a very compact and versatile switchbox.”

The use of Flexible Printed Circuit Boards (FPCB) contributes to the organic packaging of the switchbox’s complex internals. Rubber contacts were used for the contact points between the board and the switches to improve water resistance and click feel.

What the team sought were switches with intuitive and universal usability: “Our goal was to contribute to a purer riding experience by reducing stresses and unwanted distractions when on the bike, and we’re happy if we’ve managed to accomplish that.”